Internal Training System

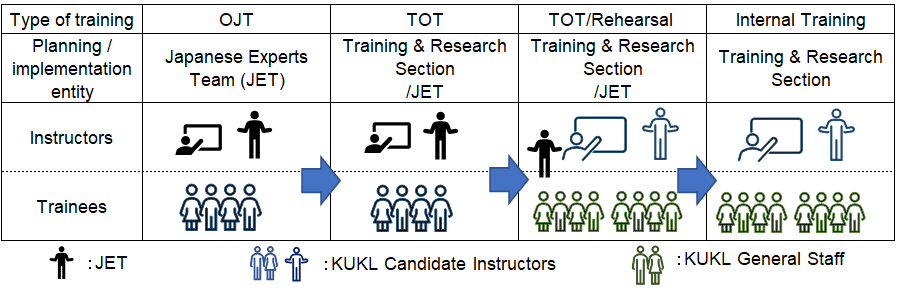

This Project will improve the capacity of KUKL to conduct internal training by preparing a management manual for conducting internal training, establishing internal training courses and modules in the technical fields covered by the Project and cultivating internal trainers.

This will help to establish an internal training system which will sustain the transferred skills in KUKL in the future.

- Top Page

- Internal Training System

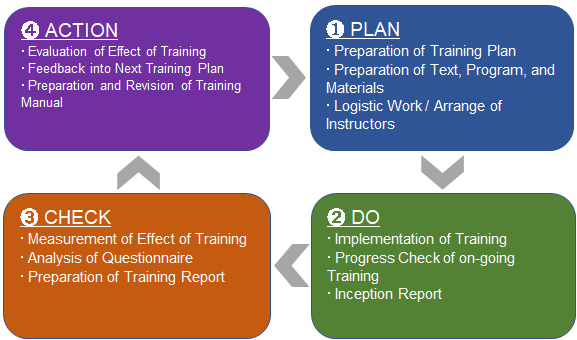

Steps towards establishing a training system

Japanese experts and KUKL staffs will work together to establish an internal training system of KUKL and to practice the PDCA cycle related to internal training in cooperation with the technical department/section.

Then, the Project will enhance the organizational structure of human resource development that is the basis of water supply business management.

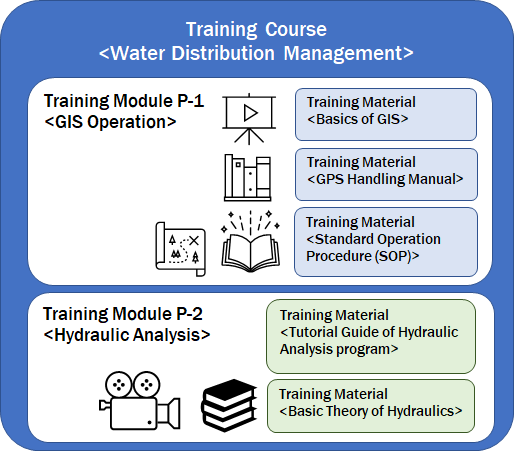

Image of Training Module Assembly

- Training Course:

- Technical courses consisting of several training modules

- Training Module:

- Training parts limited to specific technical fields

- Training Material:

- Manuals, procedures, teaching materials, and reference data for each training theme

Ahthorized Trainers

| Training Course | Training Module | Trainer | Section/Position |

|---|---|---|---|

| Water Distribution Management | GIS Operation | Name of trainer | Name of Department/Section |

| Name of trainer | Name of Department/Section | ||

| GIS Management | Name of trainer | Name of Department/Section | |

| Name of trainer | Name of Department/Section | ||

| Hydraulic Analysis | Name of trainer | Name of Department/Section | |

| Name of trainer | Name of Department/Section | ||

| Water Distribution Management | Name of trainer | Name of Department/Section | |

| NRW Management | Basics of NRW Management (Commercial Losses) | Name of trainer | Name of Department/Section |

| Name of trainer | Name of Department/Section | ||

| Meter Accuracy Test | Name of trainer | Name of Department/Section | |

| Name of trainer | Name of Department/Section | ||

| Prevension of Illegal Connection | Name of trainer | Name of Department/Section | |

| Input & Check of Water Consumption Data | Name of trainer | Name of Department/Section | |

| Water Quality Management | Water Quality Control | Name of trainer | Name of Department/Section |

| Name of trainer | Name of Department/Section | ||

| Name of trainer | Name of Department/Section | ||

| Water Treatment | Name of trainer | Name of Department/Section | |

| Name of trainer | Name of Department/Section | ||

| Name of trainer | Name of Department/Section | ||

| Customer Service | Customer Care | Name of trainer | Name of Department/Section |

| Name of trainer | Name of Department/Section | ||

| Meter Reading | Name of trainer | Name of Department/Section |